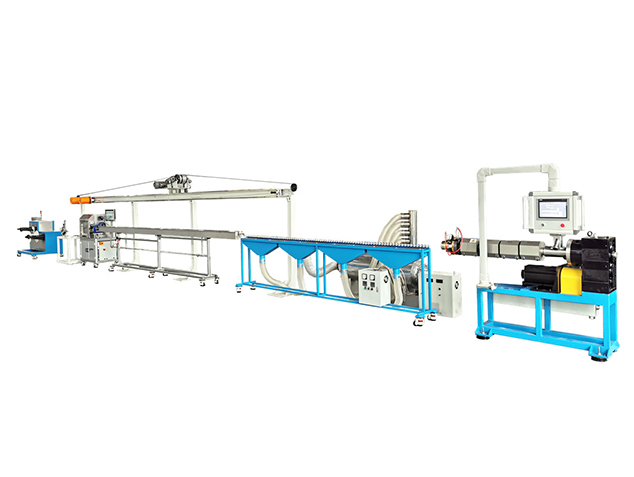

3D Printer Filament Extrusion Line (Air Cooling)

-

Production speed:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Product accuracy:

2.9mm-3.0mm, 1.70-1.80mm. (Maximum +/-0.05mm, average +/-0.03mm, CPK ≥1.6).

Product Information

With the popularization and application of 3D printing technology, based on the basis of conventional PLA and ABS materials, the development and application of special materials with better performance are also gradually developed, such as PEEK and PVA. PEEK (polyether ether ketone) is a kind of special engineering plastic with high temperature resistance, self-lubrication, easy processing and high mechanical strength and other excellent properties. It can be manufactured and processed into a variety of mechanical parts, such as automobile gear, oil screen, shift start plate; Aircraft engine parts, automatic washing machine wheel, medical instrument parts, etc. PEEK material excellent performance combined with 3D printing technology, will be widely used in automobile, aviation, medical and other industries in the transmission processing is extremely difficult to achieve parts processing requirements.

Our advantage

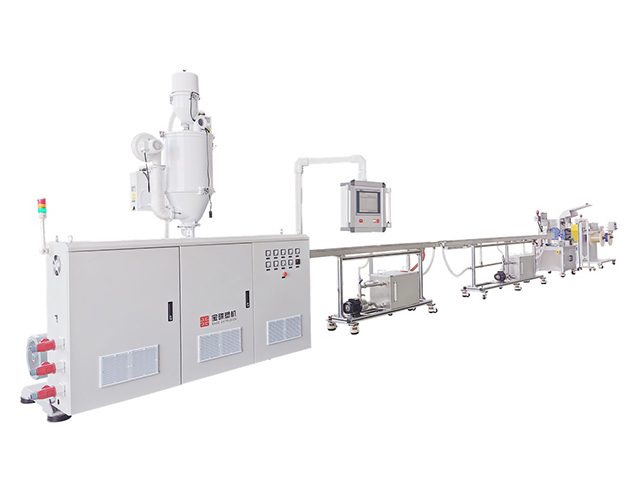

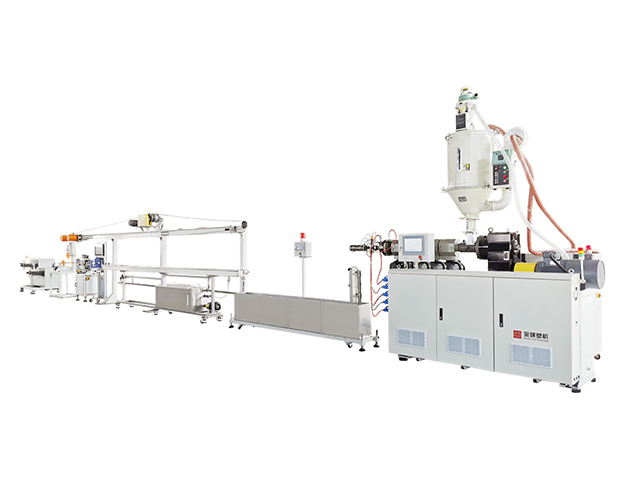

Production Line Features

- The whole line is equipped with full SERVO drive to ensure stable operation of each technological link of extrusion, such as discharge, melt measurement, traction, etc.;

- Adopt the cast copper heater, which can meet the extrusion processing temperature up to 500℃;

- Equipped with metering pump system, to ensure the accuracy of melt material extrusion, increase the die head pressure to avoid hollow inside;

- Special design of hot air cooling molding function tank, suitable for PEEK high temperature material, PVA water soluble material cooling molding process;

- Equipped with on-line OD detection and automatic feedback control function, the product dimension tolerance is controlled to the minimum to improve the automation level of the whole line;

- Servo wiring traverse +PLC program control to achieve online precision and neat winding, both large and small spool can be used for neat winding.