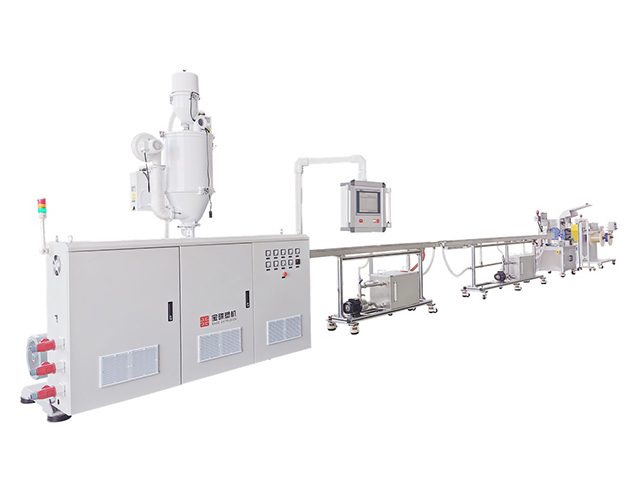

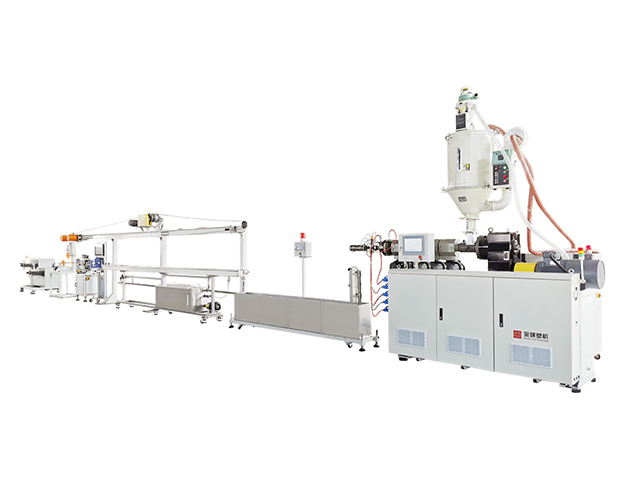

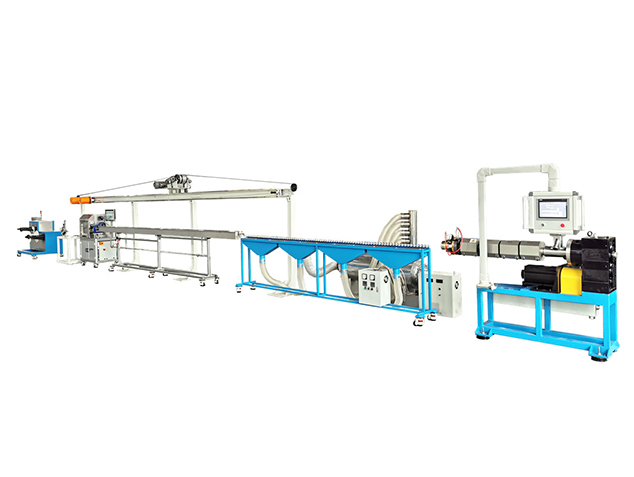

3D Printer Filament Extrusion Line (Standard Type)

-

Production speed:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Control accuracy:

Φ3.0 mm to 2.9 mm, 1.70 to 1.80 mm. (Max ≤±0.04mm, Average≤±0.03mm, CPK≥1.6).

Product Information

The shape of a 3D printer plastic filament are solid round wire at the present, the main raw material has PLA, PVA, HIPS, ABS, PC, PA, TPU etc., products range from 1.75 mm to 3.0 mm diameter. BAOD EXTRUSION provided the first set 3D PRINTER FILAMENT extrusion machine to customers in 2009, after a long time continuous improvement of equipment configuration and extrusion technology, we have formed a set of perfect specialized for 3D printing consumables extrusion line, match with supporting different screw and die molding technology, can satisfy with different kinds of materials’ production.

Our advantage

Features Of Machine Line

1. Full SERVO drivingis equipped on whole machine line, lead to high stable running for each parts on extrusion line, such as melt extruding, melt metering, pulling, etc.;

2. Equipped with metering pump system, redouble ensure precision of the melt flow, meanwhile increase the die head pressure to avoid hollow inside of wire;

3. Equipped with online diameter laser gauge and automatic diameter feedback control function, control the dimension tolerance to a minimum value, raise the level of the whole line automation;

4. Winding and traversing by SERVO drive & PLC program control to realize online precise and orderly (neat) winding, winding available for both large and small spool.