There Are Two Kinds Of Extrusion Processes

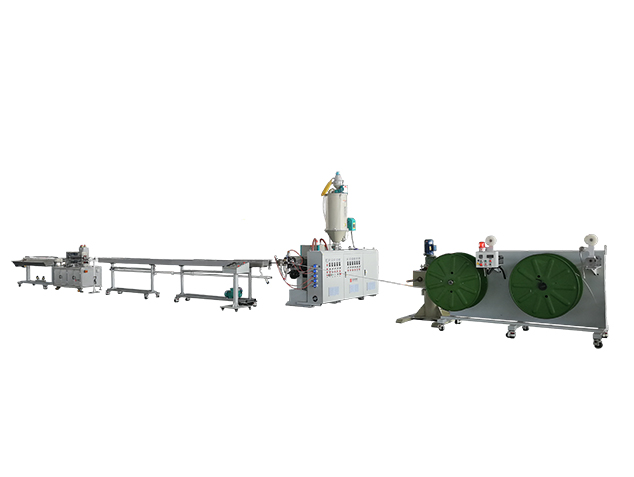

Two-step method: Inner layer tube extrusion & winding → unwinding braiding → unwinding outer layer coating and winding/cutting;

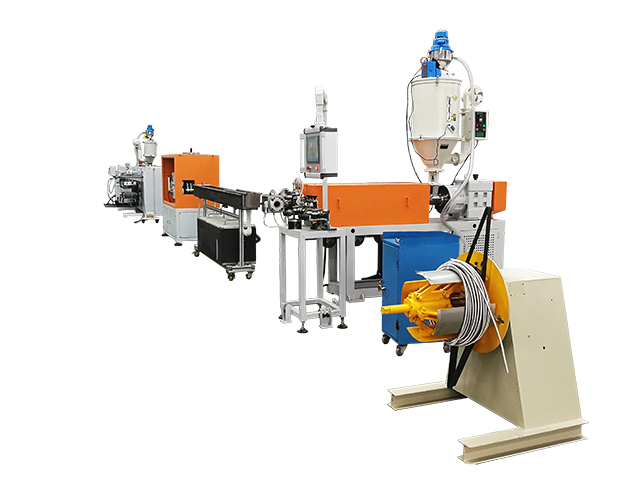

One-step method: Extruding inner tube → online braiding → online coating extruding outer layer → winding/cutting.

Our advantage

Production Line Features

- The whole line is equipped with full SERVO drive to ensure stable operation of each technological link of extrusion, such as discharge, melt measurement, traction, etc;

- Adopt the cast copper heater, which can meet the extrusion processing temperature up to 500℃;

- Equipped with metering pump system, to ensure the accuracy of melt material extrusion, increase the die head pressure to avoid hollow inside;

- Special design of hot air cooling molding function tank, suitable for PEEK high temperature material, PVA water soluble material cooling molding process;

- Equipped with on-line OD detection and automatic feedback control function, the product dimension tolerance is controlled to the minimum to improve the automation level of the whole line;

- Servo wiring traverse +PLC program control to achieve online precision and neat winding, both large and small spool can be used for neat winding.