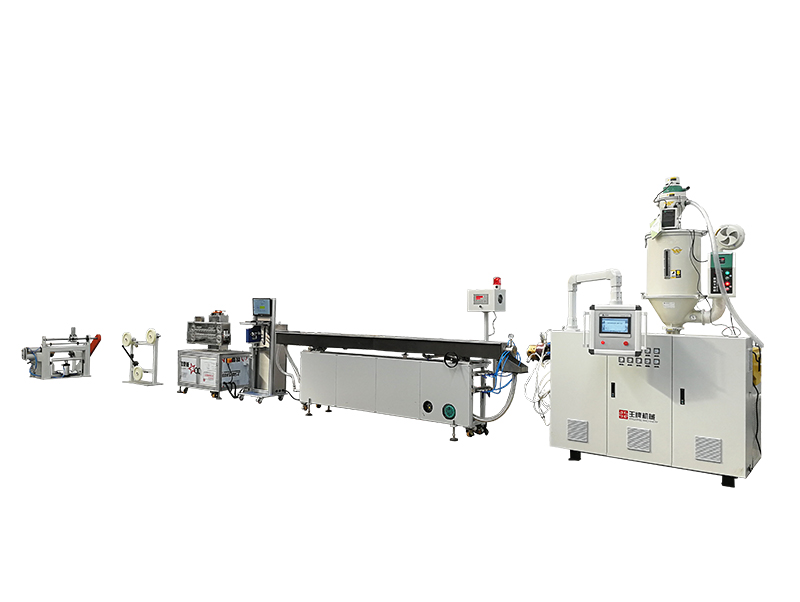

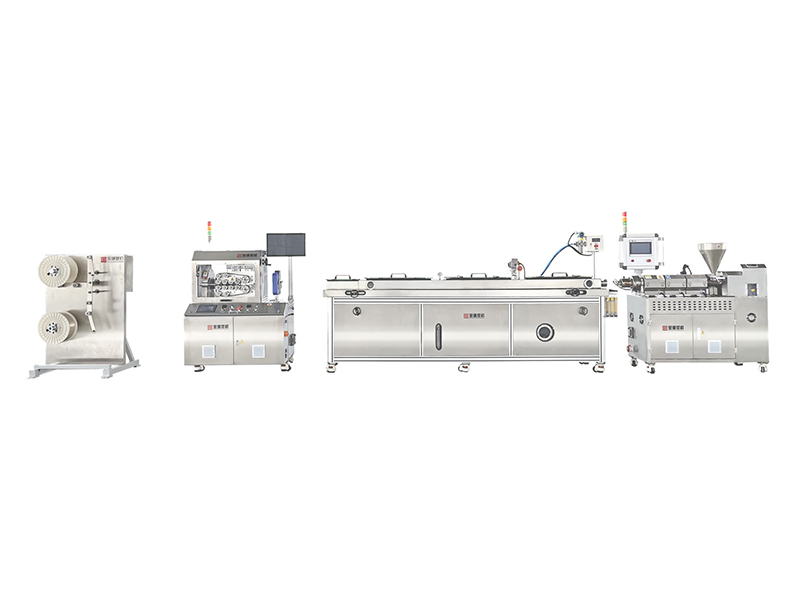

Equipment Features

- High automated production line equipped with specially designed high-pressure positive displacement die ensures precise, stable and high-speed extrusion;

- With the new vacuum control technology: vacuum and water system controlled separately. In this way, we can coordinate the multi-level water balance control system with the vacuum system, ensuring stable vacuum degree, cooling water level and water flow;

- BETA Laser measuring system, forming closed-loop feedback control, eliminating diameter deviation on-line;

- Puller equipped with multi-layer wear-resisting synchronous belt, without sliding phenomenon. High-level precision roller drive traction, YASKAWA Servo driving system or ABB AC driving system, realize extremely stable pulling;

- Based on Servo driving system, Japan Mitsubishi PLC programmable control and SIEMENS human computer interface, cutter can realize precision continuous cutting, timing cutting, length counting cutting, etc. Cutting length can be set freely, and cutting times can be set automatically, which can meet with different cutting requirements of different lengths.

Our advantage

Main Technical Parameter

|

Model |

Process pipe diameter range (mm) |

Screw diameter (mm) |

L/D |

Main power (KW) |

Output (Kg/h) |

|

SXG-30 |

1.0~6.0 |

30 |

28-30 |

5.5 |

5-10 |

|

SXG-45 |

2.5~8.0 |

45 |

28-30 |

15 |

25-30 |

|

SXG-50 |

3.5~12.0 |

50 |

28-30 |

18.5 |

32-40 |

|

SXG-65 |

5.0~16.0 |

65 |

28-30 |

30/37 |

60-75 |

|

SXG-75 |

6.0~20.0 |

75 |

28-30 |

37/45 |

80-100 |

Specification Of Pe/Pp Small Tube And Production Status Reference

|

OD(mm) |

Producing speed (m/min) |

Diameter control accuracy (≤mm) |

|

≤4.0 |

65-120 |

±0.04 |

|

≤6.0 |

45-80 |

±0.05 |

|

≤8.0 |

30-48 |

±0.05 |

|

≤10.0 |

23-32 |

±0.08 |

|

≤12.0 |

18-26 |

±0.10 |

|

≤16.0 |

10-18 |

±0.10 |

Cutting Accuracy Reference

| Cutting length |

≤50mm |

≤400mm |

≤1000mm |

≤2000mm |

| Cutting accuracy |

±0.5mm |

±1.5mm |

±2.5mm |

±4.0mm |