Multi-Layer PA Smooth / Corrugated Hose/ Tube Extrusion Line

-

Application of extrusion tube :

water tube for battery cooling (New energy electric automobile)

-

Extrusion tube structure :

Outer/Middle/Inner layer - PA/TIE/PP

Our Characteristics

This product has two, three, four and five multilayer tube/hose and other kinds, outside diameter from 6mm to 30mm. PA multi-layer composite hose/tube can effectively reduce the automobile emission pollution to the environment, and meet the higher environmental requirements. At the same time multi-layer composite hose possesses excellent resistance to penetration performance, can satisfy the EU-III standards.

Extrusion tube specification

- Tube OD: φ8-25mm

- Wall Thickness: 1.0-2.0mm

- Three Layer Wall Thickness Distribution: PA–0.75mm / TIE–0.15mm / PP-0.6mm

Production efficiency

| Outside diameter/Inside diameter: mm | Production speed: m/min |

|---|---|

| 8.0/6.0 ±0.10 | 50~70 |

| 10.0/8.0 ±0.10 | 30~40 |

| 12.0/9.5 ±0.10 | 20~30 |

| 19.0/16.0 ±0.10 | 15~18 |

| 21.0/19.0 ±0.10 | 12~15 |

Our advantage

Brief Introduction

With the development requirements of vehicle lightweight, energy conservation and emission reduction, and the penetration rate of new energy vehicles increasing year by year, multi-layer PA (nylon) tubes are more and more widely used in vehicles. The main types are:

• 3-layer smooth tube for cooling system (PA / TIE / PP & TPV)

• 3-layer corrugated tube for cooling system (PA / TIE / PP)

• 2 / 3 / 5-layer smooth / corrugated tubes for oil circuit system (PA / TIE / EVOH / TIE / PA)

Among them, 3-layer smooth / corrugated tubes used in cooling system of new energy vehicles is currently the mainstream development direction, and the market potential is huge.

Our Advantage

Innovation and technological upgrading are inseparable from practice. Based on BAOD Extrusion company’s extremely mature precision small tube extrusion process technology and experience. Since 2015, we have developed a five-layer PA automotive fuel hose extrusion molding mold on the basis of mature three-layer/four-layer precision tube extrusion mold. With the support of Zumbach and iNOEX, we invested in PA five-layer tube extrusion line in 2015, and we continuously improved the runner design of 5-layer mold within 2years. In June 2017, the performance of the five-layer PA tube/hose samples produced by our testing line reached QC/ t-798-2008 industry quality standard. At present, our multi-layers tube/hose extrusion line has the same technology as the extrusion line from Europe or US, and has successfully delivered quite a few production lines.

Product Details

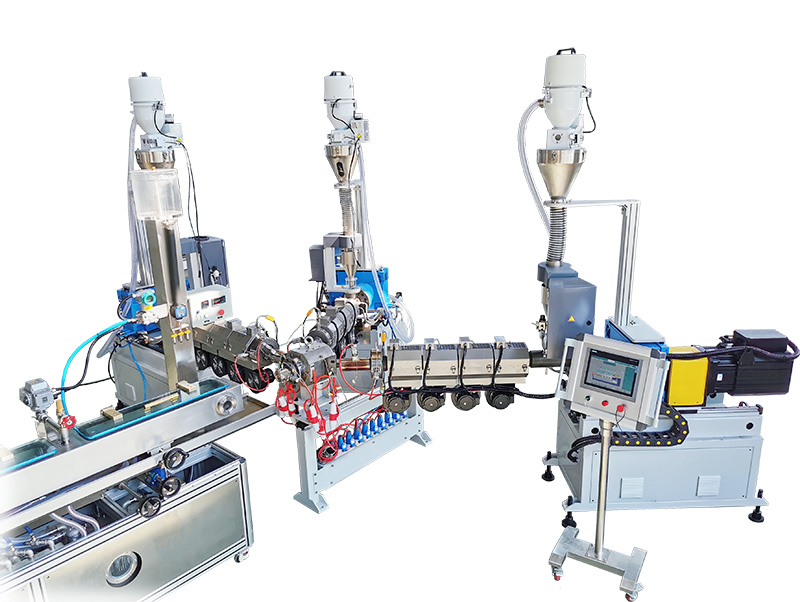

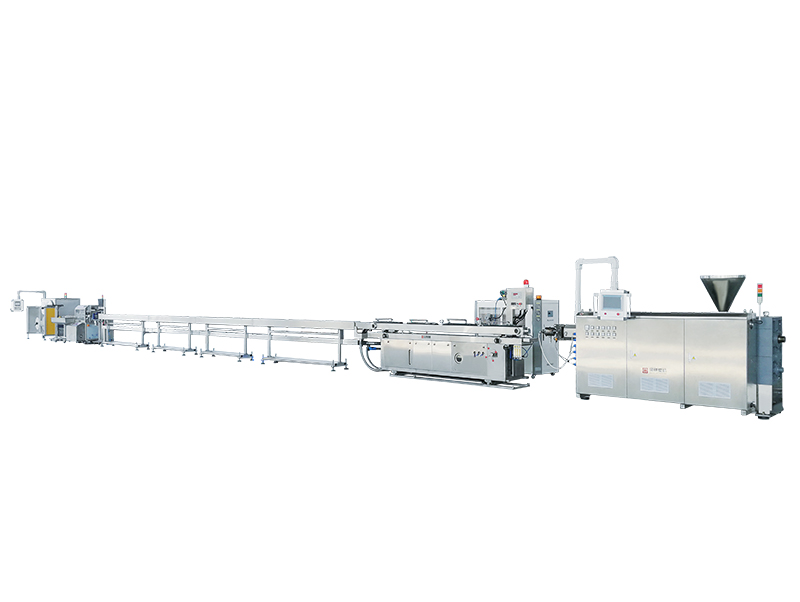

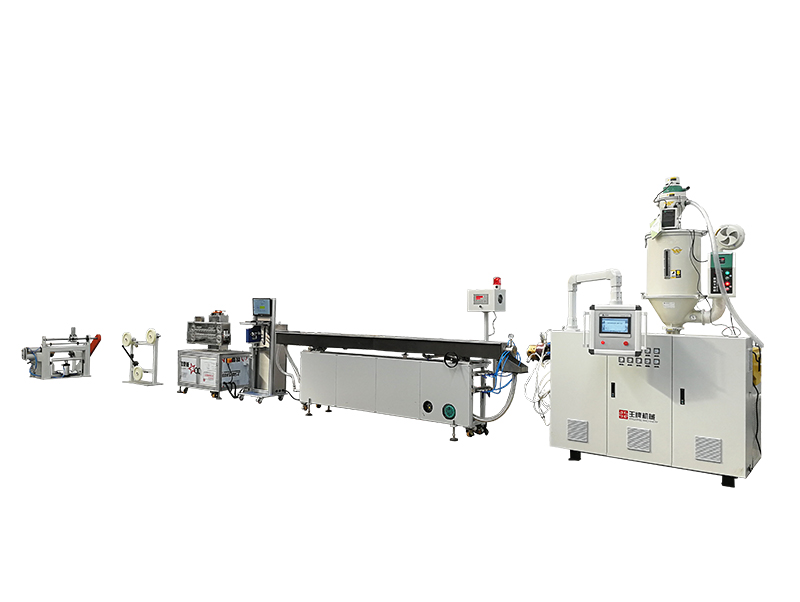

The multi-layer extrusion unit can be combined with a smooth tube or corruaged hose forming auxiliary line, and achieve the extrusion production of multi-layer nylon smooth tube and multi-layer nylon corrugated hose on the same machine line: