At Medtec China 2024, BAOD Extrusion introduced its latest innovation: a state-of-the-art FEP tube extrusion line designed specifically for high-temperature materials such as fluoroplastics, PFA, and PVDF.

One of the key features of this tube extrusion line is its ability to maintain tight dimensional tolerances, ensuring that each tube produced meets the highest standards required for medical applications. This precision control is crucial for applications such as fluid management systems, where even minor deviations can lead to significant issues in performance and safety.

In addition to its precise control capabilities, the extrusion line is designed to be space-efficient. By optimizing the layout and integrating advanced technologies, BAOD has created a compact solution that requires less floor space without compromising on performance. This makes it an ideal choice for manufacturers looking to maximize their production capabilities in limited environments.

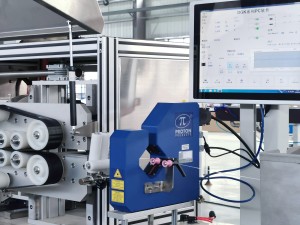

Automation is another hallmark of this new tube extrusion line. Equipped with cutting-edge control systems, the line facilitates seamless operation and monitoring, significantly reducing the need for manual intervention. This not only enhances productivity but also minimizes the risk of human error, further ensuring the consistency and quality of the produced medical tubing.

The new FEP precision medical tubing extrusion line embodies BAOD’s commitment to innovation and quality. By focusing on precision, space-saving design, and automation, BAOD EXTRUSION is providing customers with a competitive edge in the rapidly evolving medical sector.

For more information on the FEP precision medical tubing extrusion line, please feel free to contact at any time.

Post time: Sep-29-2024