BAOD EXTRUSION will be mass-delivered in January 2025., rolling out a range of innovative tube extrusion production lines, particularly in the automotive and medical tubing sectors. As a key player in the plastic extrusion industry, BAOD EXTRUSION is dedicated to developing high-performance, high-quality tube extrusion line, helping customers improve production efficiency, reduce energy consumption, and meet the increasing demand for high-quality tubing products.

The tube extrusion lines going to be delivery have a wide range of applications. In the automotive tubing sector, the products cover cooling system, fuel system, air conditioning pipeline, braking system, wire harness casing, and more. They offer excellent resistance to high temperatures, corrosion, and wear, ensuring enhanced safety and environmental performance for modern vehicles. In the medical tubing field, BAOD EXTRUSION’s tube extrusion lines utilize advanced technology to ensure precision and stability, meeting the strict accuracy and safety requirements of the healthcare industry.

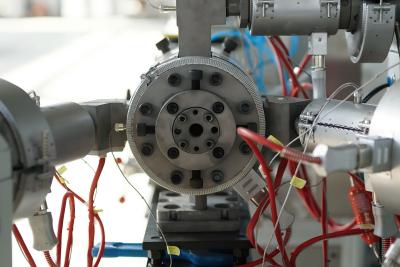

Looking ahead, BAOD EXTRUSION will continue to invest in research and development, further driving product diversification and upgrades. For example, the three-layer nylon pipe extrusion line, which will be shipped this time, can greatly improve the mechanical properties of the pipe, including tensile strength, compressive strength and abrasion resistance, through the combination of different materials. This enables the pipe to maintain stable performance under complex environments such as high pressure and high temperature.

BAOD EXTRUSION warmly invites global customers to visit and engage in discussions, exploring the latest technological solutions. We believe that through in-depth communication and cooperation, they can open up broader business opportunities and achieve mutually beneficial growth.

Post time: Jan-07-2025