In recent years, the rapid development of 3D printing technology has reshaped industries around the world. With the popularity of 3D printing applications, domestic and foreign governments have noticed the importance of 3D printer filament extrusion production lines. These production lines play a vital role in producing high-quality filaments, and in order to promote the sustainable development of the industry, a number of preferential policies and forms have been formulated.

Domestically, governments have implemented a series of support measures to incentivize investment in 3D printer filament extrusion line facilities and technology. Tax incentives and subsidies encourage businesses to embrace this area of innovation. In addition, governments have established regulatory frameworks to ensure transparent procedures and strict quality control to maintain high standards in the field of 3D printing production.

Internationally, collaboration and partnerships have become the driving force for growth in the 3D printer filament extrusion line industry. Countries around the world are pooling resources, knowledge and expertise to promote technological advancement. These collaborations not only encourage the exchange of innovative ideas but also lay the foundation for global standards in quality, safety and efficiency.

In pursuit of sustainability and environmental responsibility, governments have also taken steps to promote the use of biodegradable materials in filament production. This improves the production of environmentally friendly products and encourages the adoption of sustainable printing practices.

Additionally, governments around the world have made significant investments in research and development (R&D) to promote advancements in the field of additive manufacturing. This funding supports research programs aimed at improving the performance, efficiency and affordability of 3D printer filament extrusion lines. These resources drive industry growth and competitiveness by encouraging the adoption of cutting-edge technologies such as air cooling systems.

In summary, domestic and foreign governments recognize the key role of 3D printer filament extrusion production lines and have introduced favorable policies and forms to stimulate its development. From tax incentives and regulatory frameworks to international collaboration and R&D funding, these measures drive technological progress, ensure quality control, promote sustainability and pave the way for continued growth in this important segment of the additive manufacturing industry.

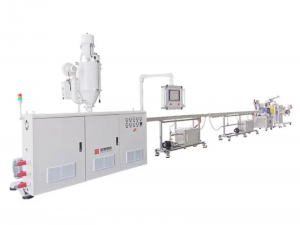

BAOD EXTRUISON brand founded in 2002, dedicated to designing, manufacturing and sales service of plastic extrusion equipment. Long - term focus on research and development for Precision extrusion technology,High efficiency extrusion technology, Highly automation in extrusion process,Safety protection of extrusion equipment. We are committed to researching and producing 3D printer filament extrusion production lines, if you are interested in our company and our products, you can contact us.

Post time: Oct-25-2023