Features of BAOD EXTRUSION PA,PU tube extrusion line:

● The first generation of “SXG” series PA/PU precision tube extrusion line made by BAOD EXTRUSION: in 2003

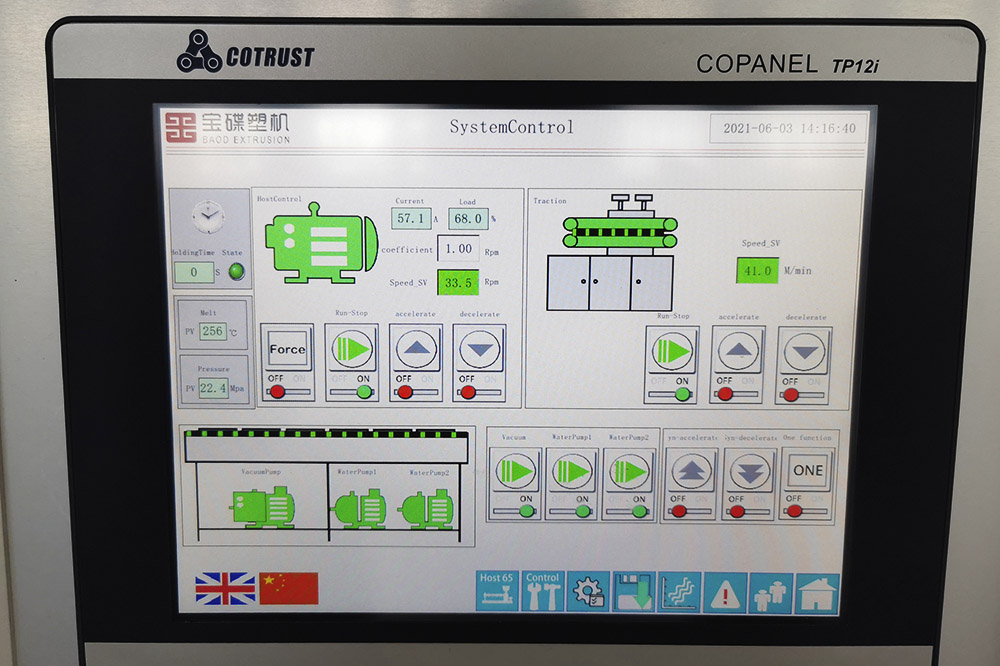

● At the present: The latest precision tube extrusion line with high production speed (Max 300meter/min) and ‘Comprehensive safety protection, closed-loop function, product data tracing, error prevention function etc.’ high level of automation.

● Production speed for reference:

¢6x4mm 60-80m/min;

¢8x6mm 45-60m/min;

CPK value ≥ 1.33.

● 20 years of experience in plastic extrusion R&D and design, with rich professional screw design ability of different materials in the plastic industry, with good plasticizing effect and stable extrusion output;

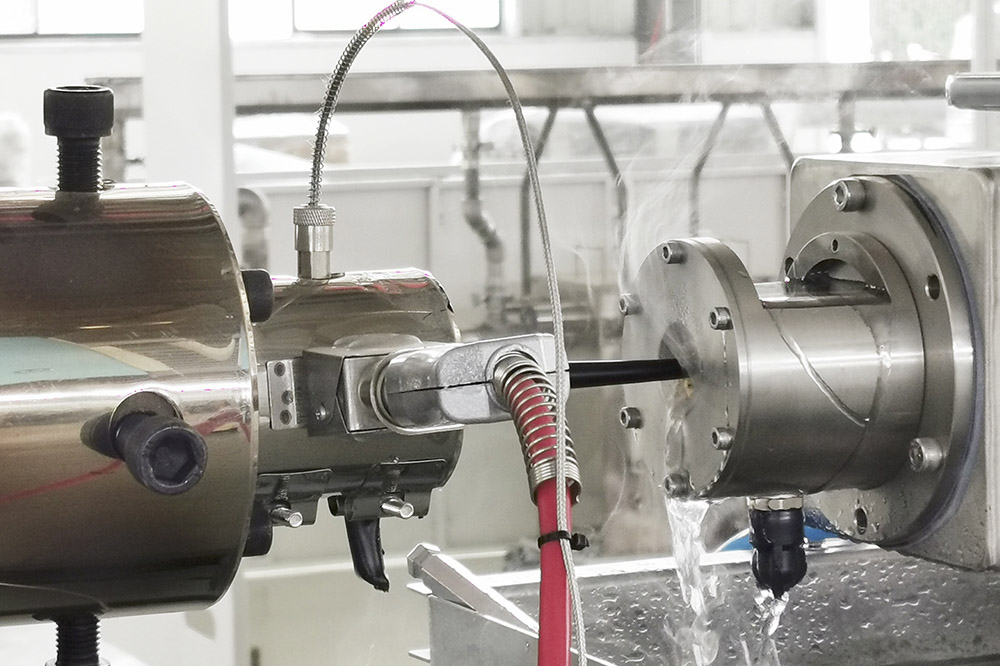

● Specially designed high pressure volumetric mold provides stable extrusion of melt form tube;

● Specially designed vacuum calibration cooling system to maintain accurate and stable vacuum negative pressure and water level in the production process;

● Dual servo direct drive puller can meet the high efficiency and stable traction within the range of 0 - 300 m/min;

● The specially designed servo-driven flying knife cutting machine can realize small-diameter tube precise length cutting or continuous cutting on-line.

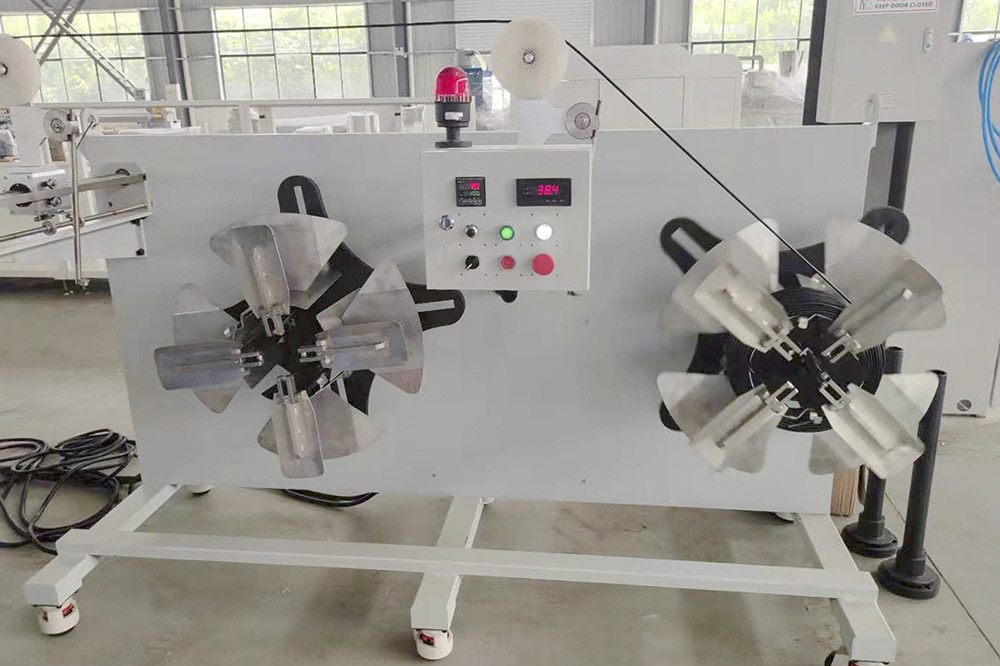

● Winding machine can provide automatic spool-changing function, eliminating manual spool-changing. The servo programmable system controls the winding and traversing actions to realize neat and uncrossed winding.

Brief

●PA tube

Due to its excellent resistance against bending, fatigue, stretch, chemical corrosion and gasoline, diesel oil, lubricating oil as well as smooth inner wall, PA ( nylon) tube has been widely applied in automobile fuel oil system, braking system, special medium conveying and other areas, with high additional product value and ideal market prospect.

●PU tube

PU(polyurethane) tube features wonderful resistance performance against high pressure, vibration, corrosion, bending and weather, in addition, with the properties of convenient and flexible, this kind of tube is widely applied to air-pressure tube, pneumatic components, liquid conveying pipe and protection tube etc. The particularity of PA/PU tube application requires extrusion equipment to have the basic characteristics of "precise size control and high efficiency".

Post time: Jun-22-2021