1. Development Background:

In 2007, BAOD EXTRUSION successfully developed the first TPV automotive seal extrusion line and delivered it to JYCO Shanghai, seizing the opportunity of the development trend of the automotive seal industry began to replace EPDM by TPV, later on, had established long-term cooperation with international famous enterprises such as Saargummi, Hutchinson, Kinugawa, Cooper-Standard, Magna, Henniges, Standardprofil and so on to supply special extrusion equipment for TPV automotive seal. At the same time, BAOD EXTRUSION keeps long-term close technical exchanges and cooperation with TPV raw material suppliers. After more than ten years of technical accumulation, BAOD EXTRUSION’s TPV extrusion process system and equipment performance have been improved day by day. Grow into a leading equipment supplier in the TPV extrusion industry.

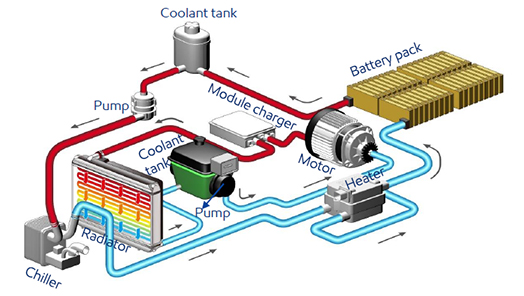

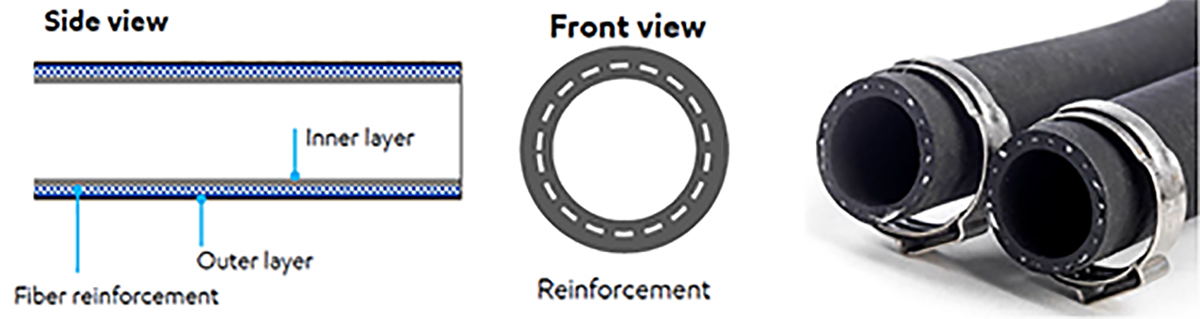

With the development of new energy vehicles, TPV materials, which are more environmentally friendly and lightweight, a new cooling water TPV knitting hose that can replace EPDM knitted hose in new energy vehicle battery system has attracted attention. In 2017, Santoprene, a well-known raw material supplier, cooperated with BAOD EXTRUSION to develop TPV knitting composite hose products. Through the long-term continuous adjustment of extrusion proofing test, scientific and meticulous process demonstration, the development of TPV knitting composite hose had achieved good results, and successfully passed the performance test of pressure resistance, stripping strength and subsequent road test, became the automobile factory recognized cooling system pipeline composition and promoted.

In 2019, BAOD EXTRUSION successfully delivered the first "TPV knitting composite hose/tube extrusion line" to well-known user in the industry, becoming the first Chinese TPV knitting line supplier with complete TPV knitting composite hose production technology. In the following years, with the rapid development of the market, BAOD EXTRUSION and many well-known domestic and international automobile pipeline manufacturers reached the "TPV knitting composite tube extrusion line" project cooperation, achieved high standard mass production of TPV knitting line, the whole line technology is fully mature, BAOD EXTRUSION has become one of the preferred suppliers of "TPV knitted composite pipe extrusion line" in the global market.

2. Advantages of BAOD EXTRUSION "TPV knitting composite tube/hose extrusion line":

● 15 YEARSof professional extrusion technology and process experience for TPV thermoplastic elastomers, including screw, extrusion mold, sizing system etc.;

● The First Chinese Brand with complete TPV knitted composite tube process technology production line supplying, including the coordinated and unified control of knitting machine and knitting defect scanning;

● 5 core TPV precision tube extrusion technology PATENTS. Based on the experience of the whole line projects and the accumulation of the proficient TPV extrusion process, it has a special extrusion molding process for the coordination of the inner and outer tubes of the TPV knitted composite tube;

● The unique precise weak vacuum sizing system perfectly matches the extrusion and calibration of TPV elastomer hoses.

● > 12 SETS of successful cases, highly standardized batch manufacturing, Ensure the whole line manufacturing process accurate and long-term stable operation.

Post time: Feb-03-2023