Product Information

Compared with general plastics and engineering plastics, fluorine plastics have more excellent and various physical properties, such as within a wide temperature range, it features unique hardness, wear resistance, resistance to chemical and heat resistance. In the application requirements constantly improving medical, automotive industry, communication industry etc, fluorine plastic pipe has more and more application.

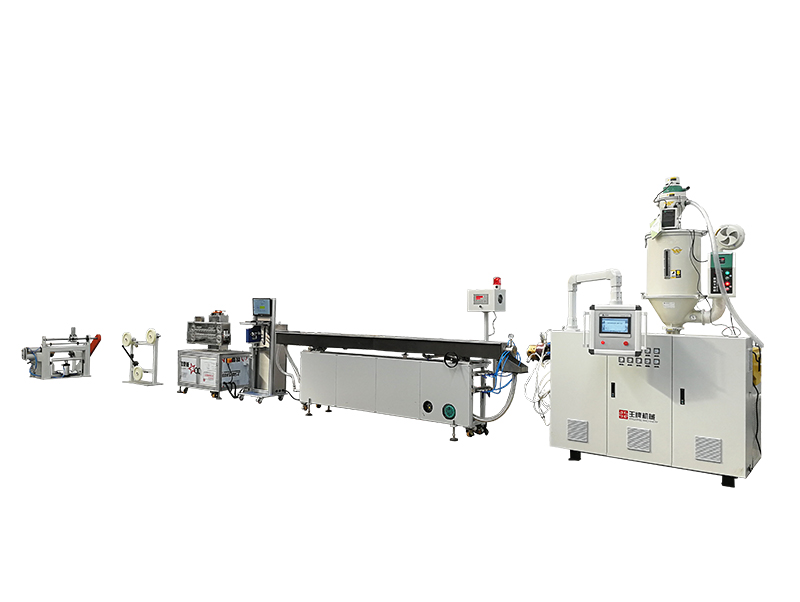

For fluorine plastic extrusion molding, KINGSWEL Machinery BAODIE company has several years research, development and debugging results, especially in medical fluorine plastic conduit and multilayer composite automobile tubing products, can provide mature and stable complete sets of extrusion equipment, debug process guidance, and a full range of turnkey service.

Our advantage

Fluorine Plastic Pipe Extrusion Line Features

- The barrel and screw of extruder adopt new #3 mold steel material, with good corrosion resistance and high temperature resistant, can meet fluorine plastic extrusion plasticizing processing.

- The heating of the barrel is made of copper or cast steel heater, can meet the stable production of the highest processing temperature 500 ℃.

- The die adopts advanced CNC processing technology and electrochemical machining method for the precision processing, meet a diameter range≤1.0mm catheter ideal forming;

- Mold material is also new #3 mold steel, with good corrosion resistance and high temperature resistant performance;

- Adopting the new concept "weak vacuum forming" technology: vacuum and water system separately control, through the multi-stage water balance control system and vacuum system unified coordination to ensure the production process is vacuum stable, cooling water surface smooth and flow stable.

- Vacuum control uses a more precise way, can achieve control accuracy of -0.01KPa level;

- Different fluorine plastics have different processing temperature, melt viscosity, liquidity and so on, the corresponding calibration means also have a great variety: vacuum dry calibration, vacuum immersion bath calibration, internal pressure calibration and the other different ways.