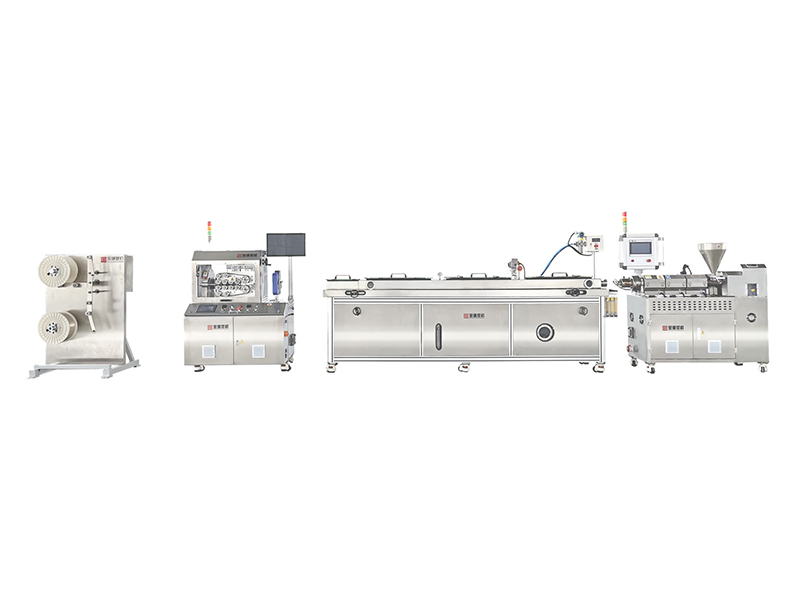

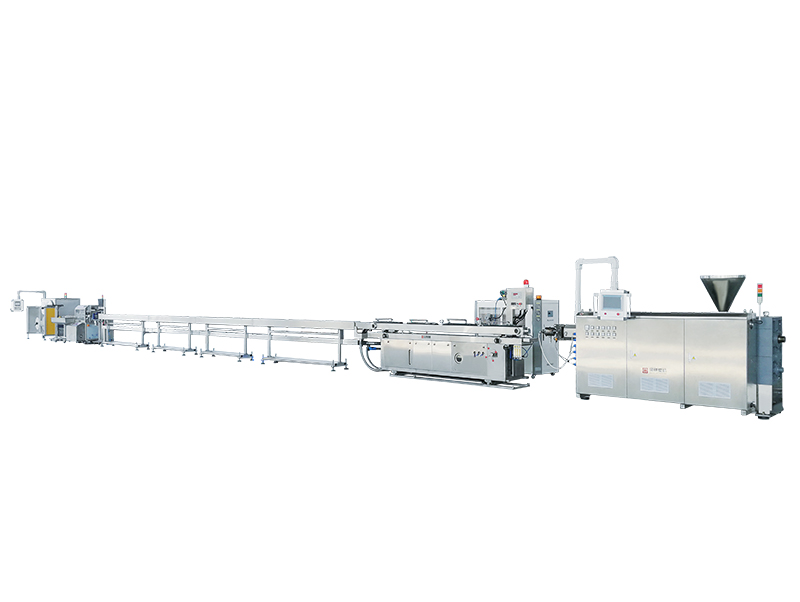

Product Information

After years of R&D and improving medical tube extrusion equipment, we have established good market foundation, and cooperated with and supplied machines to several famous Medical Products Companies., such as: Fresenius Medical Care, GAMBRO Medical Products, NIPRO CORPORATION, Meditechsystem, BJD Medical, WEGO Group, TERUMO Corporation, Epic International, ITL Healthcare etc.

Our advantage

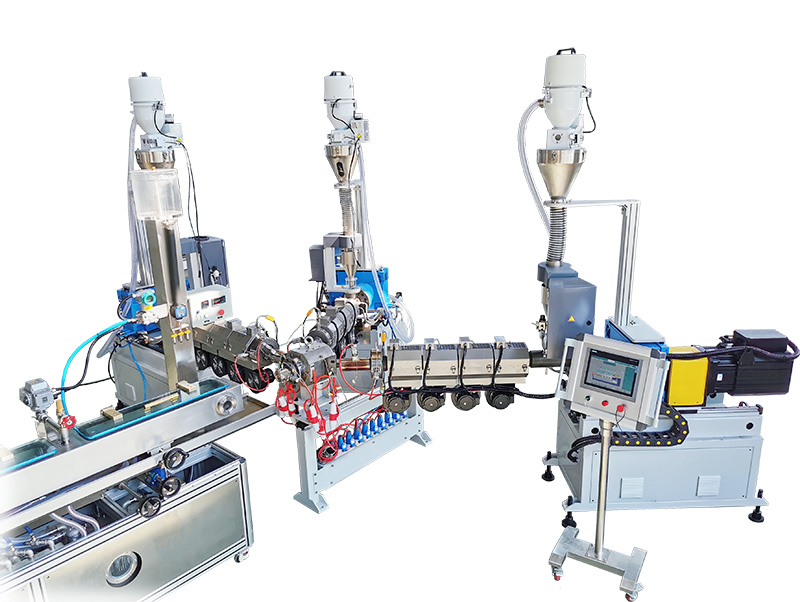

Features of Equipments

- Optimum design Screw and driving system, with excellent extrusion and plasticization effect;

- Core rods and die are made of S136 mould steel material, which ensures the inner flow surface glossiness and anti-corrosion. Structure of mold adopts “high pressure volumetric type”, which is initiated by our company, can provide stable and high-speed extrusion for the tube material with tiny fluctuation.

- With the new "accurate control of weak vacuum" technology: vacuum and water system are controlled separately. In this way, we can coordinate the multilevel water balance control system with vacuum system, ensuring stable vacuum degree, cooling water level and water flowing;

- Adopt LaserMike bi-direction high speed diameter measurement system for measuring diameter on line, measuring precision can reach ±0.001MM;

- Puller adopt imported multilayer composite wearable strap (in accordance with medical sanitary requirements), with high level precision roller, SERVO motor driving offer high stability pulling;

- Cutter equips with low inertia aluminum alloy rotating knife arm structure, driven and controlled by Servo system, which offers high speed and high accuracy cutting action. With Japan Mitsubishi PLC programmable control and SIEMENS human-computer interface, cutter can realize continuous cutting, timing cutting, length counting cutting etc. Cutting length can be freely set, automatic counting.

Base Technical Parameter Of Extrusion Line

|

Model |

Processing pipe diameter range (mm) |

Screw diameter (mm) |

L/D |

Main motor power (KW) |

Capacity (Kg/h) |

|

SXG-30 |

0.2~3.0 |

30 |

25-28 |

3.7/5.5 |

5-10 |

|

SXG-45 |

1.5~8.0 |

45 |

25-28 |

11/15 |

24-38 |

|

SXG-50 |

2.0~12.0 |

50 |

28-30 |

15/18.5 |

30-45 |

|

SXG-65 |

3.0~16.0 |

65 |

28-30 |

30/37 |

55-80 |

|

SXG-75 |

4.0~25.0 |

75 |

28-30 |

37/45 |

70-110 |

Production Status For Reference

|

OD (mm) |

Producing speed (m/min) |

Control precision ≤mm |

|

≤1.0 |

100-180 |

±0.01 |

|

≤3.3 |

60-160 |

±0.02 |

|

≤4.5 |

45-160 |

±0.04 |

|

≤5.3 |

40-120 |

±0.05 |

|

≤7.0 |

35-80 |

±0.06 |

|

≤9.3 |

25-40 |

±0.07 |

|

≤12.0 |

16-35 |

±0.10 |

Length Precision Standard

| Cuttinglength |

≤50mm |

≤300mm |

≤1000mm |

| Control precision |

±0.5mm |

±1.0mm |

±2.0mm |