Products

-

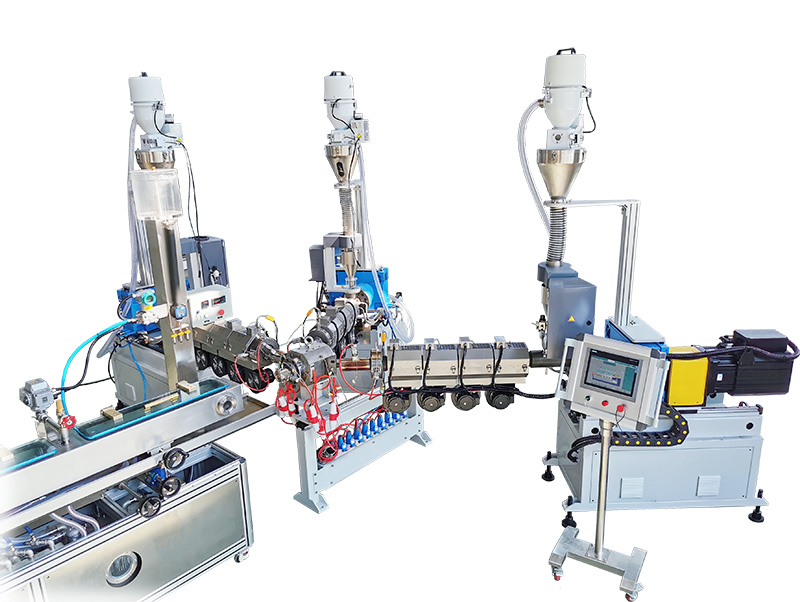

Precision Small Diameter Tube/Pipe Extrusion Line

SXG Series Precision Tube Extrusion Machine is a kind of equipment specially designed and manufactured by BAOD EXTRUSION Institute for the production of all kinds of precise small-caliber tubes (medical tubes, PA/TPV/PPA/PPS/TPEE/PUR precise automobile tubes/hoses, pneumatic tubes, high-pressure liquid conveyor tubes, multi-layer composite tubes, packaged beverages or cleaning suction tubes, precise communication optical cables, military detonator tubes, etc.) .

-

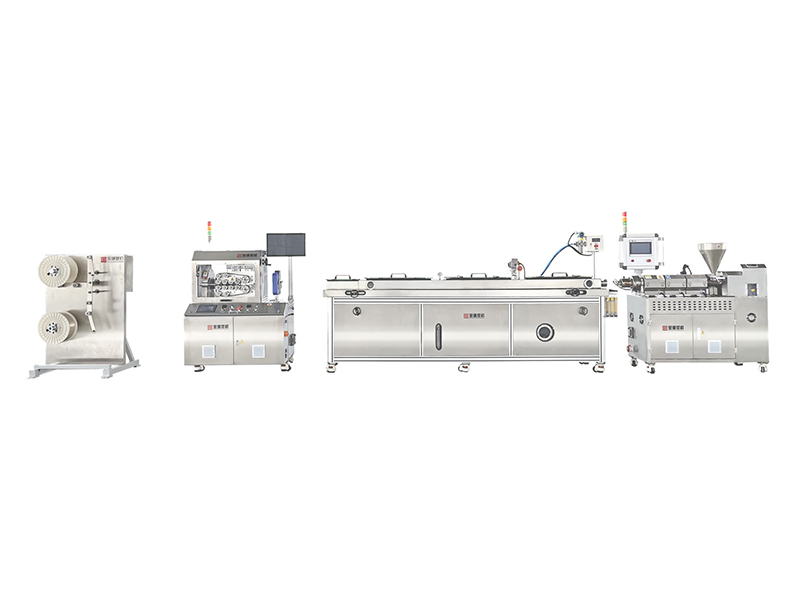

Multi-Layer PA Smooth / Corrugated Hose/ Tube Extrusion Line

Multi-layer co-extrusion technology development, make tube physical properties and cost control has great development space, such as environmental protection performance of multilayer automotive tubing, high pressure resistance performance of multi-layer braided hose, casing wall lubrication performance etc. In recent years, PA multilayer composite hose/tube of automotive fuel system is internationally widely used in car fuel oil system which features a kind of portable, high performance and environmental protection line products.

-

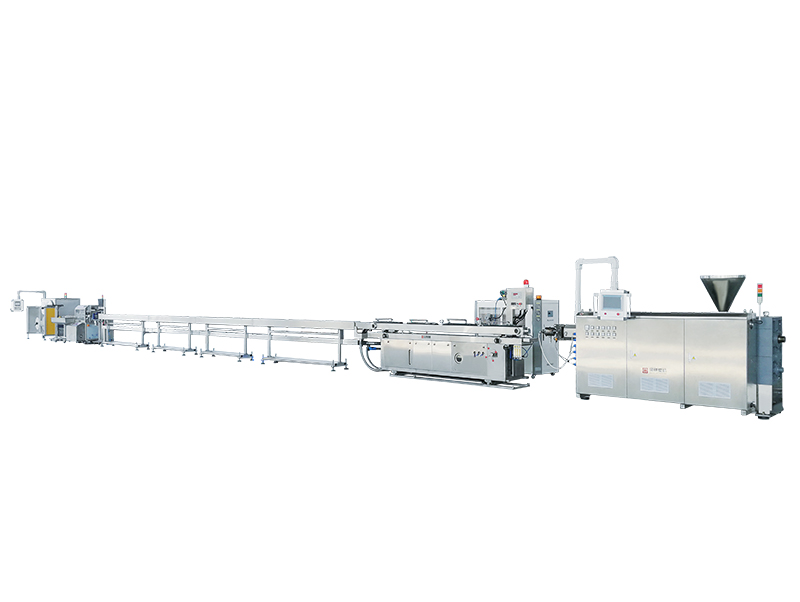

Precision Medical Tube Extrusion Line

Medical tube extrusion line is used for producing various kinds of specification medical catheter like angiography catheter, multi-lumen tubes, hemodialysis tube, infusion tube, urethral catheter, central venous catheter, epidural anesthesia tube, capillary tube, stomach tube, porous tube etc. Cover almost all kinds of polymer, including the largest amount of soft PVC.

The particularity of medical application requires extrusion equipment to have the basic characteristics of “Precise size control and high efficiency”.

Medical tube extrusion line is one of product of “SXG” series precision tube extrusion line, which is the core machinery product of BAOD EXTRUSION. By virtue of ”accurate control of weak vacuum calibration” and ”high pressure volumetric extrusion” forming technology, BAOD’s medical tube extrusion line features with incredible extrusion speed (Max 180m/min), unusual extrusion stability and high control accuracy of tube size (CPK value≥1.67).

-

High Speed PVC Medical Tube Extrusion Line

SPVC material is the largest usage amount and the most widely used material in medical tube industry, such as PVC infusion tube, dialysis tube, gas intubation, oxygen mask pipe that we are familiar with etc.

The first set of SPVC medical tube extrusion production line of KINGSWEL MACHINERY BAODIE Company can be traced back to the 1990s, until now it has nearly 20 years research and development accumulation as well as debugging experience of medical SPVC polyester extrusion technology. We constantly improve the SPVC precision medical tube extrusion process (screw structure, die structure, vacuum forming method and control accuracy, as well as the precision of hauling speed), make the stability of the molding speed and size of the pipe accuracy control get continued higher. Now the third generation “SXG-T” series high-speed SPVC medical pipe extrusion line can achieve stable production with astonishing speed of 180 m/minutes, under the condition of meeting tube size volatility (CPK value≥1.67).

In view of the widespread workshop length limitation problem in medical cleaning room, we have developed the second-stage tank with “synchronous coiling cooling”, it can realize super cooling effect in short tank, and tube’s precision is out of affection. This can help clients realize capacity multiple increased without changing the existing plant.

-

PA (Nylon) Precision Tube Extrusion Line

Due to its excellent resistance against bending, fatigue, stretching, chemical corrosion and gasoline, diesel oil, lubricating oil as well as smooth inner wall, PA (nylon) pipe has been widely applied in automotive fuel oil system, braking system, special medium conveying and other areas, with high additional product value and ideal market prospect. Existing materials for automotive pipeline are PA11,PA12,PA6,PA66, PA612, etc.

-

PA/PE/PP/PVC High Speed Single Wall Corrugated Pipe Extrusion Line

Different extruder and forming machine will be chosen for different material: PA, PE, PP, UPVC, etc. The pipe is mainly used for electrical cable or wire protection, drainage pipe of washing machine, pipe in dust collector, automobile industry, lamp industry and air-exhausted pipe etc.

Standard single wall high speed corrugated pipe forming machine: can produce two diameters or three diameters’ single wall corrugated pipe in the same mould blocks, which reduce the cost of the moulds and reduce the time for changing the mould blocks, increase the efficiency.

-

PU (Polyurethane) Precision Tube Extrusion Line

PU(polyurethane) tube features wonderful resistance performance against high pressure, vibration, corrosion, bending and weather, in addition, with the properties of convenient and flexible, this kind of tube is widely applied to air-pressure tube, pneumatic components, liquid conveying pipe and protection tube etc.

The particularity of PU tube application requires extrusion equipment to have the basic characteristics of “precise size control and high efficiency”.

-

Precision Fluorine Plastic Tube Extrusion Line

Fluorine plastic is paraffin polymer which part or all of the hydrogen is replaced by fluorine, they have polytetrafluoroethylene (PTFE) (not extrusion processing), total fluoride (ethylene propylene) (FEP) copolymer, poly full fluorine alkoxy (PFA) resin, polytrifluorochloroethylene (PCTFF), ethylene fluoride a vinyl chloride copolymer (ECTFE), ethylene suites fluoride (ETFE) copolymer, poly (vinylidene fluoride) (PVDF) and polyvinyl chloride (PVF).

-

LDPE,HDPE,PP Precision Tube Extrusion Line

The application of this extrusion line is to produce such as spray head of cosmetics and cleaning products, straw tube, porous filter pipe, ball-point pen refill etc .Different ranges of the pipe diameter and hardness can be customized by changing the combinations of downstream equipment.

-

HDPE Silicone Core Tube (Micro Duct) Extrusion Line

HDPE silicone core pipe, or silicone pipe for short, is one kind of new composite pipe with silica gel solid lubricant inside the pipe, the main material of which is HDPE. The pipe is widely used for communication cable system.

-

TPV,PVC Automobile Sealing Strip Extrusion Line

Automotive Seal Strip is one of the most important parts of the car, which is widely used in the door, window, car body, skylight, motor racks and backup (baggage) box and other parts, with sound insulation, dustproof, seepage control water and shock absorption function.

-

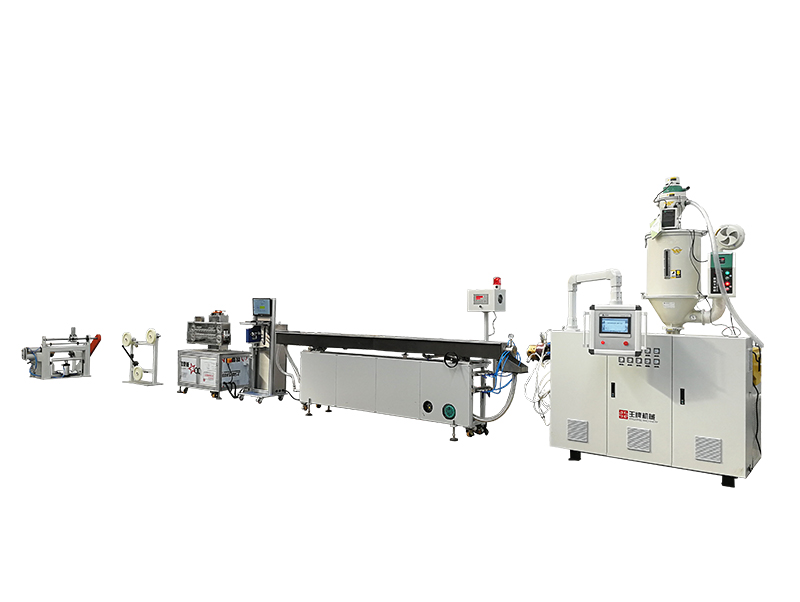

TPV Knitting Compostie Hose Extrusion Line

TPV knitting composite hose is a tube fitting product composed of inner TPV, middle knitted layer, and outer TPV. It is used as the pipeline component of the battery cooling assembly of new energy vehicles.

The TPV knitting composite tube is not only strong and flexible, but also has excellent aesthetics and sealing during the service life of the parts, and maintains a high level of performance.

TPV has easy processing and design flexibility, which helps to reduce the cost of a series of applications.

Compared with other polymeric materials such as thermoset rubber (TSR) or ethylene propylene diene monomer (EPDM) rubber, TPV offers potential sustainable development advantages such as lighter weight and more sustainable manufacturing and recycling.

(The raw material supplier is: Santoprene – Thermoplastic Vulcanizate TPV)