Products

-

FQ Series Rotary Fly Knife Cutter

PLC program control cutting action, has three type cutting mode: length cutting, time cutting and continuous cutting, can meet with different length cutting requirements on-line.

-

Puller & Fly Knife Cutter Machine

This machine is used for small precision tube pulling and cutting on-line, high speed servo motor puller and fly knife cutter on the same frame, compact structure and convenient operation.

-

SC Series Follow-Up Saw Blade Cutter

Cutting platform follow-up with extrusion product when cutting, and back to original position after cutting finished. Collection platform followed.

-

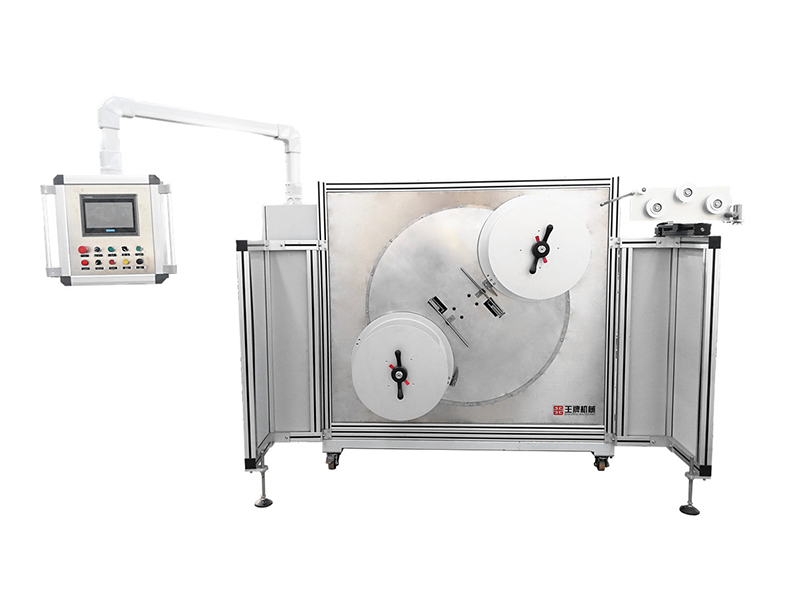

SPS-Dh Auto Precision Winding Displacement Coiler

This coiling machine adopt precision servo sliding rail to control winding displacement, coiling controlled by PLC program , full servo driving double position coiling. Machine will get proper coiling and winding displacement speed automatically after input tube OD on HMI panel.

-

Precise Traverse Displacement Auto-Spool Changing Coiling Machine

Precise traverse displacement Auto-spool changing Coiling machine

Manual coil/spool changing is almost impossible when extruding tube speed exceeds 60 m/min. In 2016, we developed a fully automatic coil/spool changing winding machine, which is used to solve the coil/spool changing process problems of various high-speed precision tube extrusion. -

Shaft Type Winding Machine

Double station structure, mechanical smooth rod traverse arrangement, users can choose different material, structure, size of reel, realize pipe products extrusion production line semi-automatic winding.

-

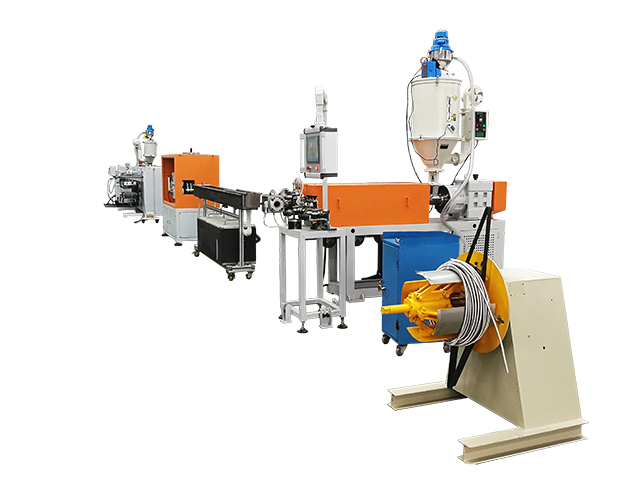

Steel Wire/ Steel Strand / Metal Corrugated Pipe/ Compensation Chain Coating Extrusion Line

This kind of plastic coating products contains automobile cable, prestressed steel strand, metal corrugated pipe coating, compensation chain coating etc. Choose high pressure coating or low pressure coating according to the compact degree of coating equipment.

-

Metal Pipe Coating Extrusion Line

Designed and manufactured by BAOD EXTRUSION, this production line is designed to coat one or more layers of PVC, PE, PP or ABS around common iron pipe, stainless steel pipe, aluminum pipe/bar, etc. Plastic coating pipe is applied in decoration, heat insulation, anti-corrosion and automobile industry.

-

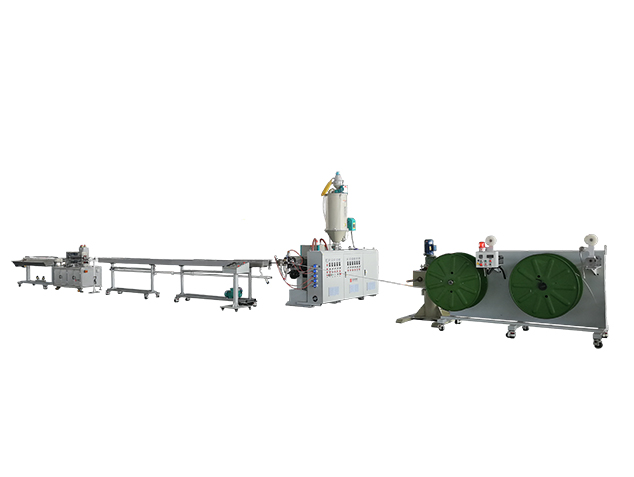

Braided Reinforced Composite Hose/Tube Extrusion Line

There are two kinds of extrusion processes:

Two-step method: Inner layer tube extrusion & winding → unwinding braiding → unwinding outer layer coating and winding/cutting;

One-step method: Extruding inner tube → online braiding → online coating extruding outer layer → winding/cutting.