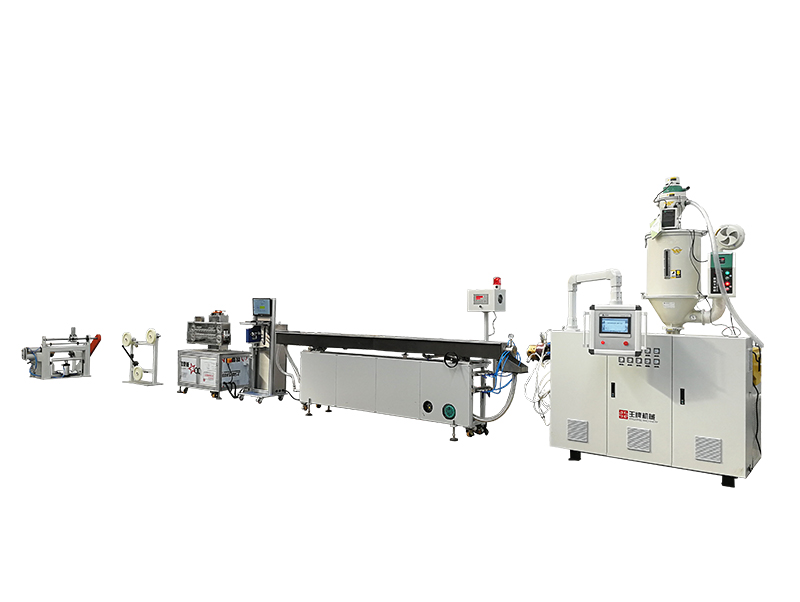

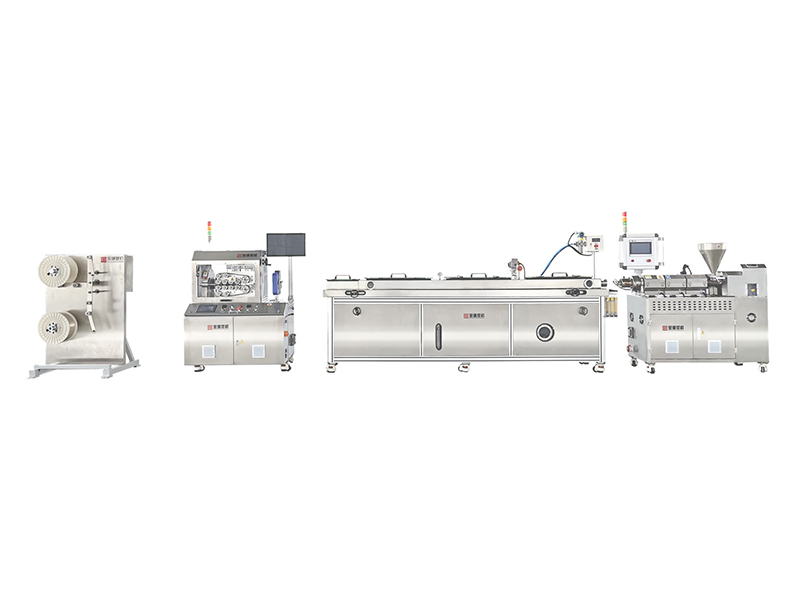

Equipment Features

- PU Screw optimized by Japanese technological processing, can perfectly adapt to the PU material which is with high thermal sensitivity, flowability and melting viscosity, thus ensuring even plasticization and high output efficiency;

- Core rods and die are made of Sweden “ASSAB” S136 die steel, precision grinding, which ensures the internal flow surface gloss and anti-corrosion. Structure of mold adopts “high pressure volumetric type”, which is initiated by our company, can provide stable and high-speed extrusion for the tube material with tiny fluctuation;

- High precision processed melt pump with moving device, flexible moving. Front and back installed with melt pressure sensor _ Italy “GEFRAN” Brand, front melt pressure closed-loop feedback control system _ Italy “GEFRAN” instrument. Offer high stable output and automatic extrusion fluctuation adjustment;

- With the new “automatic precise control of vacuum” technology: vacuum and water system controlled separately. In this way, we can coordinate the multi-level water balance control system with vacuum system, ensuring stable vacuum degree, cooling water level and water flow.

- BETA Laser measuring system, forming closed-loop feedback control, eliminating diameter deviation on-line;

- Puller equipped with multi-layer wear-resistant synchronous belt, without sliding phenomenon. High level precision roller drive traction, YASKAWA Servo driving system or ABB AC driving system, realize extremely stable pulling.

- Specially designed Winding machine with tension induction regulator, apply to soft pipes, keep winding under natural relaxation state, when tension condition change, the fluctuation within manageable scope, avoid tube overdrawn by too fast winding speed and too slow winding speed.

Our advantage

Main Technical Parameter

| Model | Process pipe diameter range (mm) | Screw diameter (mm) | L/D | Main power (KW) | Output (Kg/h) |

| SXG-45 | 2.5~8.0 | 45 | 28-30 | 15 | 18-30 |

| SXG-50 | 3.5~12.0 | 50 | 28-30 | 18.5/22 | 28-45 |

| SXG-65 | 5.0~16.0 | 65 | 28-30 | 30/37 | 55-75 |

| SXG-75 | 6.0~20.0 | 75 | 28-30 | 37/45 | 80-100 |

Specification Of Pu Small Tube And Production Status Reference

|

OD(mm) |

Producing speed (m/min) |

Diameter control accuracy (smm) |

|

≤4.0 |

30-60 |

±0.05 |

|

≤6.0 |

23-45 |

±0.05 |

|

≤8.0 |

18-35 |

±0.08 |

|

≤10.0 |

16-25 |

±0.08 |

|

≤12.0 |

14-20 |

±0.10 |

|

≤14.0 |

12-18 |

±0.10 |

|

≤16.0 |

10-15 |

±0.12 |