Product Information

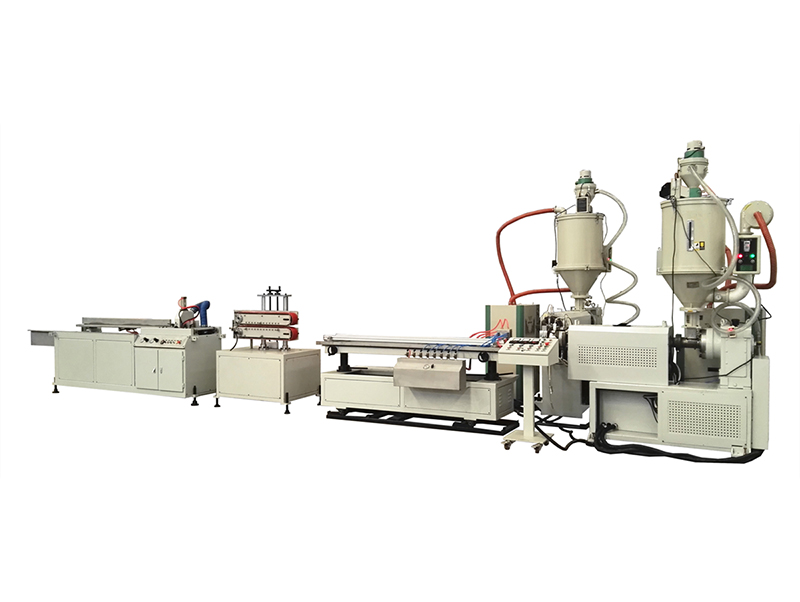

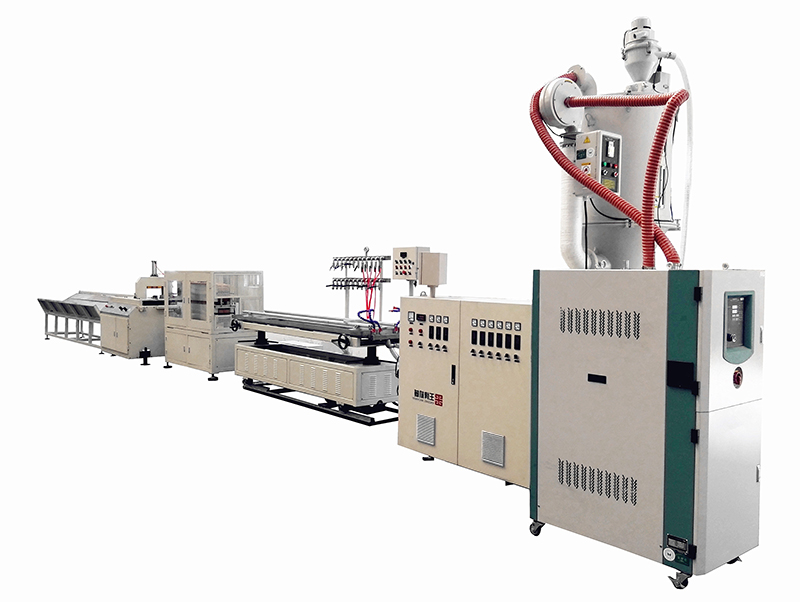

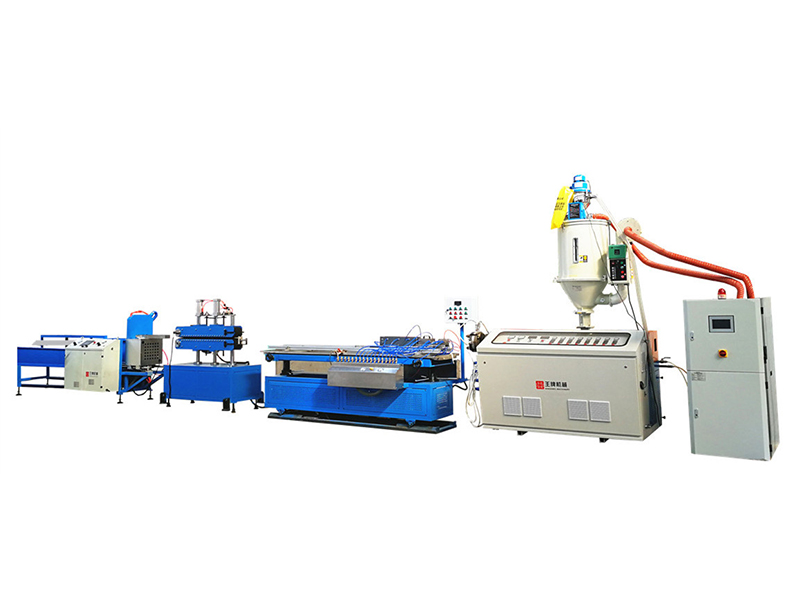

Adopt BAOD EXTRUSION designed high performance single screw extruder and multi extrusion, equipped with precision mold and auxiliary lines, it can process different automotive seal strip materials such as PVC/SPVC, TPE (TPV, TPO, TPU) and different types (hard and soft, soft hard combination, lined with alloy frame, metal fixture, tongue shape of car seal buckle, etc.); This production line is equipped with gluing machine, flocking machine, drying road etc, and can meet the requirement of automotive interior flocking strip production. Replacing the corresponding screw barrel, this production line can also be used to process the seal strip used on common mechanical device, with a wide range of application.

Through the constant cooperation with high-end users, we were able to conduct a further survey and evalution on advanced machine and technology, combined with the original Taiwan extrusion technology process and our long-term research and development of polymer seal strip extrusion process. In this way, we have formed a set of complete, highly efficient, stable extrusion technology and equipment used in seal strip production, especially for the TPV seal products which will gradually replace rubber seal products, we have greatly exceeded the domestic ordinary equipments on the shape controlling effect and capacity speed of the finished products.

In recent years we have made efforts to intensify the research and development of the domestic market, and we have won recognition and high praise from some well-known enterprises. Our end-users: Saargummi, JYCO, Vintech, Kinugawa, Toyoda Gosei, INOUE, TSUCHIYA, Great Wall Motor etc.

Our advantage

Supplementary Equipments

- Dust removal gluing machine. This machine is oriented by upper and down wheels, with imported steel structure frame glue supply equipment. It can ensure continuous automatic glue supply and smooth gelatinization.

- Flocking machine. Automatic nap recycling flocking, with automatic supply, flocking humidity control; the nap recycling device runs smoothly, stable and reliable, no jam phenomenon.

- Online hydraulic cutting machine. Hydraulic cutting machine is suitable for online cutting of lined with alloy frame seal strips. Using Japan Mitsubishi programmable controller (PLC), it can realize smooth and reliable cutting.

- Double head unreeling frame + metal strip roller forming machine.

Main Technical Parameter

| Model |

AS-SJ50 |

AS-SJ65 |

AS-SJ75 |

AS-SJ90 |

| Max width of strip process(mm) |

30 |

50 |

80 |

120 |

| Max producing speed(m/min) |

25 |

25 |

25 |

25 |

| Install power (kW) |

25.9 |

47.5 |

58.5 |

70.5 |

| Cooling water flow(m³/h) |

5 |

7 |

8 |

9 |

| Compressed air(Mpa) |

0.6 |

0.6 |

0.6 |

0.6 |